At first, because of the auto industry decided to diamond coil as a best coil type, so using adjustable wooden model is common. Process is completed, around the original coil winding machine will use the leather made wooden hammer will coil model. Despite the coiler have made every effort, but the manual and very physical process means difficult to achieve consistency.

The next development of coil manufacturing and major leap pneumatic machine is introduced. These will ring into a diamond, however, this process is not fully automated, still need to use solid wood moulding machine and some manual improvement mallet.

In the 1970 s, tractor hydraulic operating coil actually replaced the former and the hammer method. This is still not a simple or direct process, because ultimately depends on the block to produce the right to select the correct radius of coil, but with the passage of time, the experienced operator to produce the desired results and very difficult to repeat level before implementation. Although since the early days of the gavel and molding machine, the process has gone a long way, but some still need to manually adjust the contour.

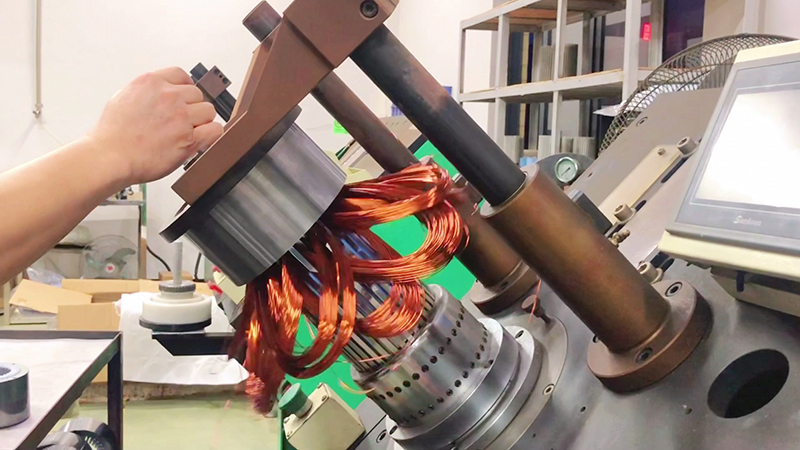

Later, as the coil loop and pull), change the manufacture of wire coil. These machines can be programmed to produce a better defined and complete drape outline of a higher quality of the coil, the coil on the vision more consistent, it is easier to winding to the stator. Machine operators will be converted into coil drawings, and then uploaded to the machine's console, produce the high quality of the coil with a consistent rules spacing. Yong kun once again at the forefront of the industry development, the new production technology greatly reduce the possibility of any damage of manufacturing process. Trailer contour accuracy repeatability means that the cooling of the air gap between the stator coil more consistent, resulting in a higher quality of the finished product of the stator.

Throughout the history of the gear reduction motor manufacturing, repeatable stator coil has been manufacturing high quality of the most difficult components.

This is provided by a single coil in a higher quality level, and improve coil insulation technology, make coil has a longer service life, meet the high demands more equipment.

Wechat scanning

Quick navigation:

home About us

ProductS workshop

news JOIN US

service contact us

Lu丨ANMICRO&SPECIAL Motor Co., Ltd

Tel: +86 564-3630212

E-mail: lwdj888@163.com

Address: No. 36, zhongdesi Road, economic and Technological Development Zone, Lu'an City, Anhui Province